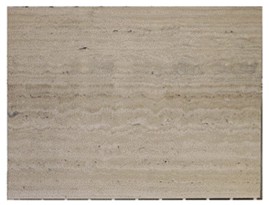

TRAVERTINO ROMANO CLASSICO

BEST-SELLERS

2025-07-04

Travertino Romano is a timeless natural stone that has characterized urban construction and interior design for centuries. The porous texture, warm and neutral tones and technical characteristics make it extremely versatile, perfect in every context and use.

TYPOLOGY: TRAVERTINE

FINISHES: BRUSHED, POLISHED, HONED, SPLIT

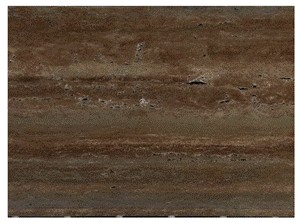

COLOUR: BEIGE, WALNUT

Origin of Travertine, a stone that resist time

Travertine is a limestone sedimentary stone that forms in a sub aircraft continental environment, where the limestone solution has had time to stagnate and sediment. The proximity to the surface and, on the contrary, the remoteness from spring water or currents, promote the formation of Travertine.

The porous structure that distinguishes its appearance is due to the presence of gas bubbles trapped during the sedimentation phase.

The word “travertine” comes from the Latin lapis tiburtinus, that is stone of Tibur, ancient name of the current city of Tivoli, in Lazio, near which there is an important quarry of this material.

The color of travertine varies from milky white to walnut, with shades ranging from yellow to red. The chromatic variety is linked to the typology of oxides incorporated in the sedimentation phase.

Characteristics of Travertine Romano Classico

The classic Roman travertine is a robust, resistant and compact natural stone, used both as a building material and as a decoration, both indoor and outdoor.

It is a type of marble used since ancient Rome for the realization of architectural works, thanks to the various colors that characterize it and its technical specifications. The most famous example of use in Roman times is undoubtedly the Colosseum, built in 70 A.D.

This sedimentary stone has excellent resistance to acid aggression, temperature ranges, heat, atmospheric and chemical agents and has a porosity not permeable to water.

It does not require major maintenance as it is extremely durable over time, which is why it is perfect in every context and use.

The main technical characteristics of TRAVERTINO CLASSICO are:

| Type of test | Standard | Unit | Medium | dev. |

| Flexural strenght | UNI EN 12372 | MPa | 11,7 | 1,6 |

| Flexural strenght after frost-thaw (48 c.) | UNI EN 12371 | MPa | 11,2 | 1,6 |

| Resistance to abrasion wear | Appendice C UNI EN 1341 | mm | 21,3 | |

| Water absorption at atmospheric pressure | UNI EN 13755 | % massa | 0,6 | |

| Apparent density | UNI EN 1936 | Kg/mc. | 2491 | |

| Termal shock – Mass change (20 cycles) | UNI EN 14066 | % | -0,06 |

Finishing of Travertine Romano Classico

Travertine Romano Classico, as well as other types of travertine, can be cut in two different ways: crosscut or veincut.

In ancient times, Travertine Romano was worked crosscut (an example is the Colosseum in Rome, built in 70 AD): this type of processing allowed to obtain slabs with a uniform and cloudy appearance.

This type of cut is made following the direction of the material, which gives each slab a unique yet similar. In this case the holes will be larger and more irregular. The crosscut materials are also suitable for the split surface, and the travertines are very suitable for this type of processing.

On the contrary, the veincut is a modern technique, in which the streaks form clear lines. The veins are very evident, as they represent the layers of sedimentation, and are very regular and constant for all the slabs of each block. The holes in this case are more regular and of reduced size, therefore it is more suitable for the various types of filling.

Travertino Romano Classico: the most appreciated finishes

Travertine slabs (Roman and non-Roman) can be subjected to multiple finishes, based on the desired aesthetic result and usage requirements.

The type of finish changes the appearance of the material, although the type of starting stone is always the same as the dominant color remains unchanged.

Among the finishes most used for Roman travertine slabs are:

- brushed, which ensures homogeneity and the silky appearance of the surface, for a result with an antique and refined effect.

- split, which highlights the characteristics of this natural stone

- polished, which offers a brilliant surface

- honed, which ensures a smooth and matte appearance.

The surface of the travertine slabs can be left to “open hole” or alternatively “filled” with natural, transparent or colored fugants to fill the holes and give uniformity to the stone.

Uses of Travertine Romano

Roman travertine is one of those materials whose texture gives a fascinating appearance to many environments, as it can heat any space.

Thanks to its characteristics, it is one of the preferred materials in the building industry, also in the urban area. Even for its different colours, it is suitable for both modern and classic environments. Roman travertine is an ideal choice for a wide range of applications both indoors and outdoors.

In indoors environments, it can be used in:

- flooring: its chromatic variations and its veins create a unique appearance; we can find it in the entrance hall, living rooms and kitchens, where it gives a touch of elegance.

- coverings: of entire walls or architectural details, such as fireplaces or columns.

- decorative elements: Travertine can be carved or shaped into different shapes to create unique decorative elements such as frames, medallions or plinths.

- work surfaces: in kitchens or bathrooms, Travertine Romano can be used to create work surfaces such as kitchen countertops, sinks or tops.

In outdoor environments, Travertine Romano is particularly suitable due to its resistance to atmospheric agents, given the geological composition and physical properties. In particular, the Travertine Romano is characterized by a low level of water absorption, thermal stability and high resistance to bending and compression, characteristics that make it ideal for:

- fountains and pools: gives a luxurious look to the surrounding environment.

- facades: the historical aspect and the durability of the material contribute to give the buildings an appearance of classical grandeur.

- outdoor flooring: as patios and courtyards.

All types of Travertine, NOT only Romano: the main types of Travertin

There are different types of Travertine, they differ according to the chromatic variation of their surface: depending on the place and depth in which the blocks are extracted, the stone can take darker or lighter shades.

Among the different types of Travertine, the most known and most used are:

Travertine Classico: classic and modern at the same time, it stands out from Travertine Romano exclusively for the extraction area. It is a light and uniform beige, porous, compact and resistant material. It can be brushed, honed and polished and is used both indoors and outdoors.

Travertine Alabastrino: mainly white, with very clear veins ranging from yellow to silver, it has a homogeneous and compact structure, generally without pores;

Travertine Noce: has always been very sought for the dark tones and the compactness of its structure, is particularly suitable for the coating of environments subject to frequent trampling;

Travertine Navona: white with ivory streaks, it is a bright, compact and homogeneous material, used in particular for flooring.

Travertine Classico and Travertine Romano Classico: availability in real time

The different types of travertine, and in particular the Travertino Classico, are one of the Best Sellers of Alberti & Alberti. The finishing processes are carried out with our machines by specialized workers both for the sawing of the slabs and for the finishing of the surfaces.

Check the availability of travertine slabs in real time on the online warehouse